|

In the rapidly evolving landscape of modern business, the supply chain stands as a critical backbone that directly influences a company's success. Efficient supply chain management is no longer a mere operational necessity; it's a strategic differentiator that can make or break an organization. With the advent of technology and data-driven approaches, predictive analytics has emerged as a game-changer, offering unprecedented opportunities to enhance supply chain processes. The Power of Predictive Analytics

Predictive analytics leverages historical data, statistical algorithms, and machine learning techniques to forecast future trends and outcomes. When applied to supply chain management, this powerful tool can revolutionize how businesses manage inventory, demand, production, and distribution. Let's delve into how predictive analytics can bring about transformative improvements:

Challenges and Considerations While predictive analytics offers remarkable benefits, its implementation requires careful consideration:

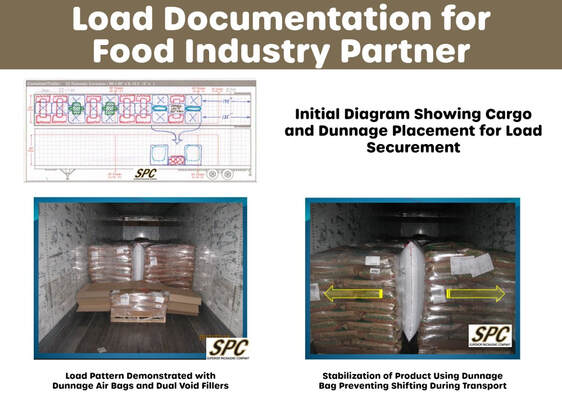

The Path Forward Predictive analytics presents an unparalleled opportunity for supply chain optimization. Businesses that embrace this technology stand to gain a competitive edge through improved operational efficiency, reduced costs, and enhanced customer satisfaction. As technology continues to advance, predictive analytics will likely become an indispensable tool, driving smarter decision-making and shaping the future of supply chain management. By harnessing the power of data, organizations can pave the way for a more agile, responsive, and successful supply chain ecosystem. Load Securement Playing It’s Part When you pair all of these factors together, and add proper load securement to the mix, the results can be quite satisfying as you watch your bottom line not only improve, but by numbers and in timeframes that you wouldn’t have thought possible even a decade ago. While people who don't work in the shipping industry may often think of it as stagnant and unchanging, the truth is that we work in an industry that is always improving for the better. We keep things moving, and we’re getting better at it every day. Truly something we should all be proud of! For more information: https://www.qualitydigest.com/inside/customer-care-article/improving-supply-chain-predictive-analytics-070523.html In the world of logistics and shipping, proper loading patterns play a crucial role in maintaining cargo safety and stability during transportation. Among the many components that contribute to secure cargo handling, dunnage—the materials used to protect and support cargo—plays a vital role. By understanding and implementing proper loading patterns for dunnage, businesses can significantly reduce the risk of damage and maximize the efficiency of their shipping operations. We will explore the essential considerations and best practices for achieving optimal loading patterns to ensure safe and secure cargo transport, and most importantly, prevent damage to your valuable goods. What exactly is Dunnage? Dunnage refers to various materials used to protect cargo from shifting, vibrating, or colliding during transit. Common types of dunnage include airbags, foam inserts, blocking and bracing materials, and other protective elements. Effective dunnage solutions prevent cargo movement, distribute weight evenly, and absorb shocks and impacts that may occur during transportation. However, simply having dunnage is not enough; it must be loaded correctly to provide optimal protection and stability. When dunnage is loaded incorrectly, it can lead to cargo shifting, imbalance, or contact with other items in the shipment. This can result in damage, breakage, or even accidents during transportation. By following appropriate loading patterns, businesses can minimize the risks associated with cargo movement and ensure that the dunnage effectively supports and protects the items being shipped. Moreover, efficient loading patterns can improve space utilization, enhance load stability, and reduce the chances of goods becoming dislodged or damaged during transit. What are the best practices for loading dunnage?

Proper loading patterns for dunnage are paramount to ensuring the safe and secure transportation of goods. By adhering to best practices and taking into account the specific characteristics of the cargo, businesses can minimize the risk of damage, reduce the potential for accidents, and optimize their shipping operations. Remember to plan carefully, distribute weight evenly, use appropriate securing and bracing techniques, and fill void spaces effectively. By implementing these loading patterns, businesses can protect their valuable cargo, enhance customer satisfaction, and maintain a strong reputation in the logistics industry. And when in doubt, contact us! We are the industry leaders in safely securing your cargo and having it arrive to its destination damage free!

|

�

Recent NewsArchives

June 2024

Categories

All

|

|

|

United States Distribution Centers

Oregon Minnesota Georgia Texas Canadian Distribution Center

Ontario |

|

Copyright © 2024 SPC. All Rights Reserved.

Site by: Superior Effect Marketing

Site by: Superior Effect Marketing