|

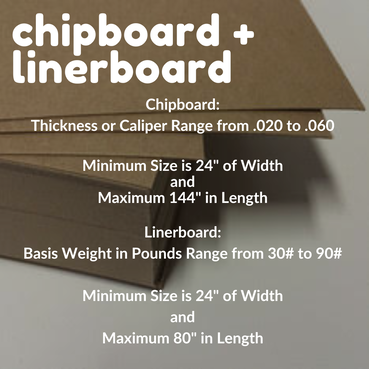

You've packed your truck, each box Tetris-ed into place. But as you hit the road, a nagging thought creeps in - will your cargo stay put when faced with highway bumps and winding corners? Fear not, intrepid transporters, for chipboard and die cuts offer a powerful one-two punch for unwavering load securement. Let us explain why these unassuming heroes deserve a starring role in your cargo stabilization arsenal.  Chipboard: The Unsung Hero of Stability Imagine a thin, sturdy shield protecting your precious cargo. That's chipboard in a nutshell. This lightweight yet robust material serves as a friction barrier, preventing boxes from sliding and toppling like dominoes. Think of it as invisible grip tape for your pallet. Moreover, chipboard's talents extend beyond mere stopgap solutions. Its versatility shines through its adaptability:

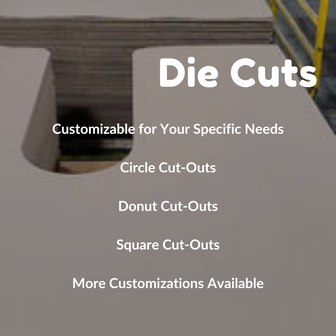

Die Cuts: Securement with Precision Chipboard is great on its own, but Die Cuts really up the ante. These meticulously shaped pieces act as strategic reinforcements, bolstering your load's securement in key areas. Think of them as custom-built puzzle pieces designed to fill every void and prevent box-to-box collisions. Here's how they elevate your securement game:

Chipboard and Die Cuts in Harmony

But the true magic unfolds when chipboard and die cuts join forces. Imagine chipboard sheets forming the secure foundation, while custom die cuts fill the gaps and provide targeted support. It's like a well-rehearsed orchestra, each element playing its part to create a harmonious symphony of stability. Here are some real-world examples of this dynamic duo in action:

Beyond the Brawn: The Benefits of Going Chipboard and Die Cut The advantages of this winning team extend beyond just rock-solid cargo control:

|

�

Recent NewsArchives

June 2024

Categories

All

|

|

|

United States Distribution Centers

Oregon Minnesota Georgia Texas Canadian Distribution Center

Ontario |

|

Copyright © 2024 SPC. All Rights Reserved.

Site by: Superior Effect Marketing

Site by: Superior Effect Marketing